Reverse engineering

Today we can share one real example from the recent past. We were contacted in order to replace a broken lens in a projector. Unfortunately there was no documentation available – drawing or a 3D model. What existed was only the one broken sample.

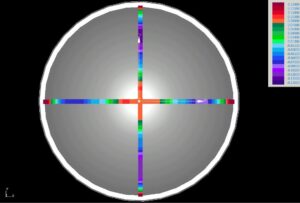

We received the sample and we glued the broken pieces together. After that we made a 3D scan and reconstructed a 3D model of the lens. Once the model was finalized with optimizing steps we compared the reconstracted model with our lens portfolio.

And here we were a bit lucky because we found a lens, which was very similar to the original one.

We shared a sample with our customer and the lens worked well!

Here is the feedback from our customer:

“I wanted to write to you. I just installed the lens this weekend and it is working as it should and the switch is working again after years of use.

Thank you again very much for your helpfulness, time and professional approach.

Sincerely…”

Devoted customer support is one of our main business strategies.

Reverse engineering is the key to accurately replicating optical components that are no longer available or require upgrades. Through advanced 3D scanning, optical simulations and precision CNC machining, we are able to create identical or even higher performing components to meet your specific needs. Learn more about this service: 3D SCANNING AND REVERSE ENGINEERING

💡If you are looking for a reliable partner for a reverse engineering project, do not hesitate to contact us.

Our experienced team is ready to work with you to find the optimal solution for your specific needs.