ECOGLASS company history

2021

The management of the company was taken over by the second family generation in September 2021, which is exactly 30 years after the company ‘s establishment. Mr. Jiří Kočárek, the company founder, is still a valuable member or R&D team. His daughter Mrs. Helena Krutská is leading the company as new CEO together with her husband Mr. Jan Krutský, Vice-Chairman of the company Board.

2020

We focused on the promotion of the company into the online world – we set up social networks, participated in online trade fairs and set up Google advertising. Our company won second place in the Vodafone Company of the Year competition in the Liberec region. We started to expand and modernize the production management offices at the production plant in Mnichovo Hradiště.

2019

The working environment was improved thanks to the air extraction system installed in the large press room.

2018

An investment was made in grinding technology for small products, with the aim of reducing dependence on suppliers and improving flexibility in production. ISO 14001 certification was introduced.

2017

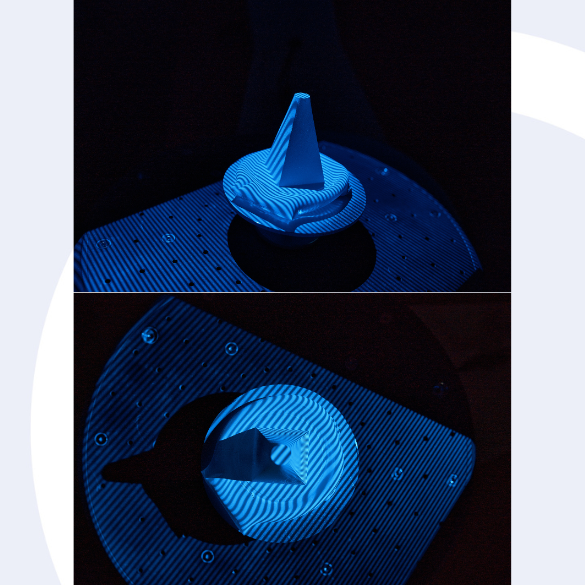

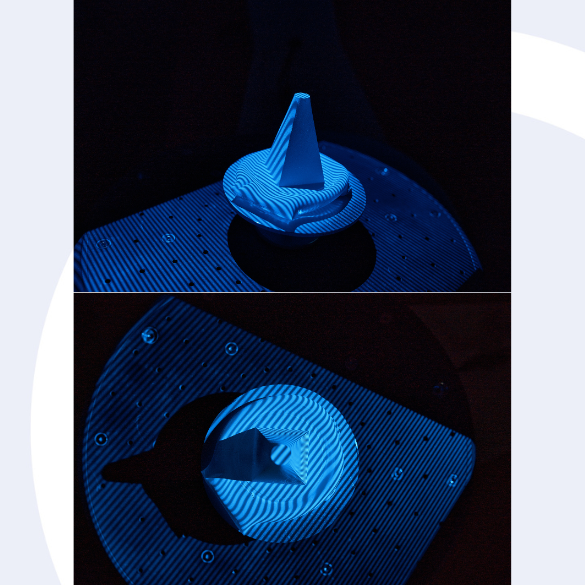

Our production is equipped with new 3D scanning technology for complex evaluation of tools and products.

2016

We finished reconstruction and extension of our production plant.

2015

We have enlarged our production facility and extended our tool manufacturing capabilities with a new CNC turning center. We were also nominated as a serial supplier in several automotive projects.

2012

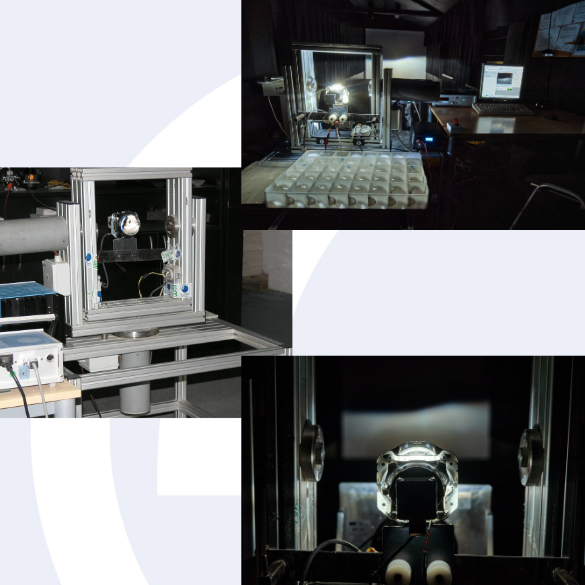

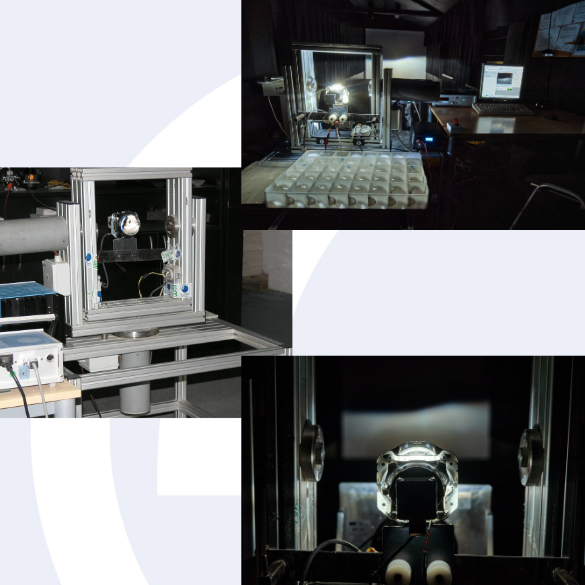

We have extended our development and testing capacities with a new light laboratory including a new goniophotometer. It accelerated our development of optics and its testing.

2010

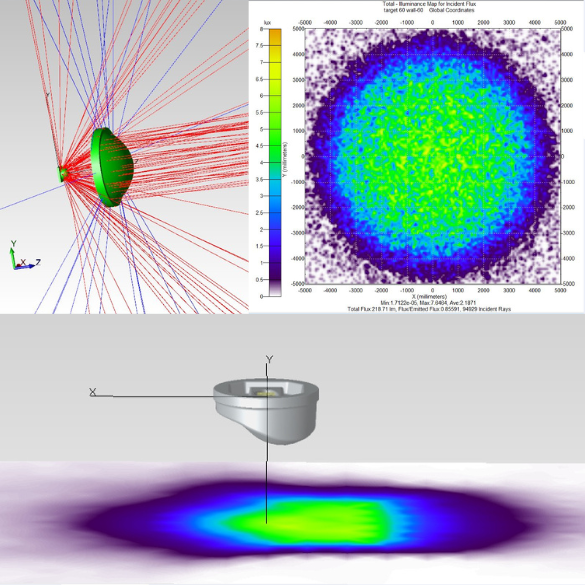

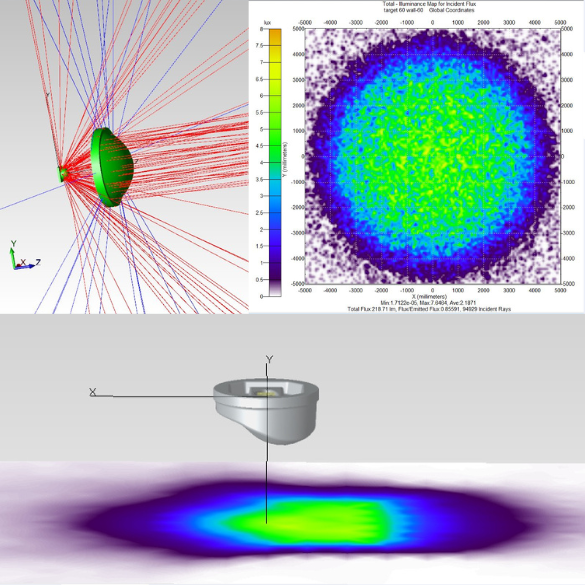

Inquiries for specific exterior lighting applications are more frequent, customers require lenses including optical design. ECOGLASS invested into software tool for optical design and simulations and started to produce lenses for LED applications.

2008

New prototype pressing machine with high production output of small lenses LED matrix displays used in traffic information signs and variable traffic signs is developed and manufactured. Production of small lenses up to 20mm is maintained in serial deliveries.

2005

We have started production of small lenses for LED matrix displays used in traffic information signs and variable traffic signs. We significantly increased production of glass parts for airport lighting. New 3D measurement device with a resolution of 2.5 microns has been purchased in order to improve inspection of tools and products. New CNC milling center is installed for tool manufacturing. This year we also won the Exporter of the Year competition in the category of small and medium-sized companies and started to reconstruct the new company headquarters.

2002

Production capacity is increased about 3 times by installation of new pressing machines.

2001

We have started deliveries of glass prisms for airfield lighting. And we also modernized and repaired our production hall.

2000

Company manufacturing activities were separated from purely commercial activities and company ownership structure was simplified. EcoGlass became a company owned by a single partner. This year we were nominated for the first time as the supplier for serial production of aspheric lens for automotive headlight – fog light Skoda Octavia.

1999

Quality management system according to ISO 9002 is implemented. Our light laboratory is equipped with precise goniophotometer for evaluation of photometrical parameters of headlamps and functional inspection of aspherical lenses.

1998

We continue on further development of the rain sensor by digitizing its functions and implementing microprocessor control. We have reached precision of molded parts at +/-0.005 mm. We gained the first orders for serial supply of aspheres for motorcycle headlights in Italy.

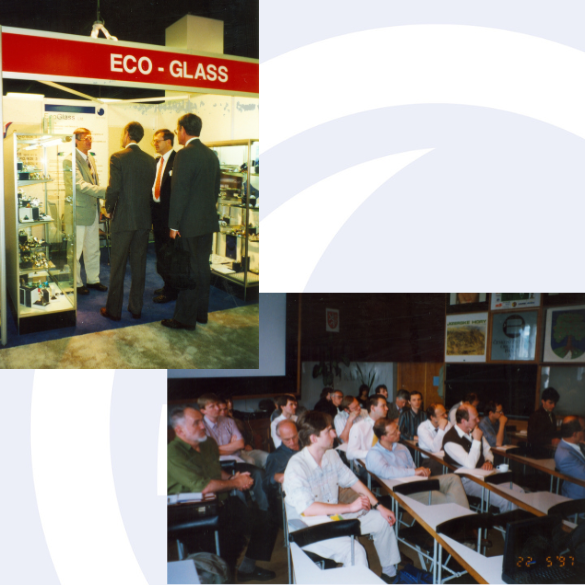

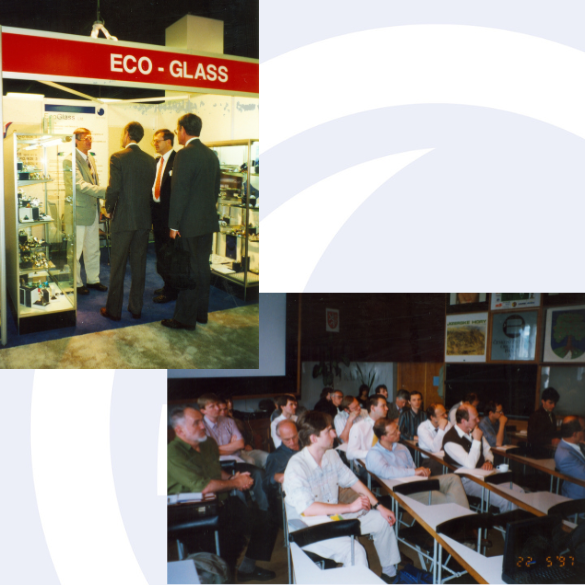

1997

Brown field manufacturing equipment purchased previous year resulted in better organization of production. Further investments into production technology bringed increase in quality and precision of the products. We started production of parts from borosilicate glass types Duran (Pyrex). This year we held the first republic conference on aspheric optics, its production and use. We exhibited abroad for the first time at the Czech Days event in Chicago.

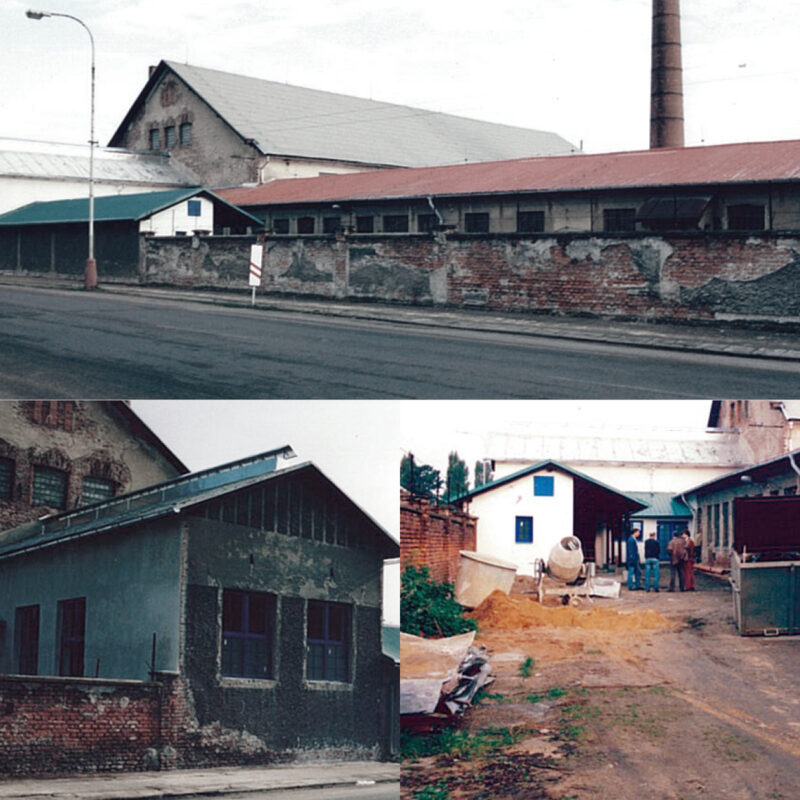

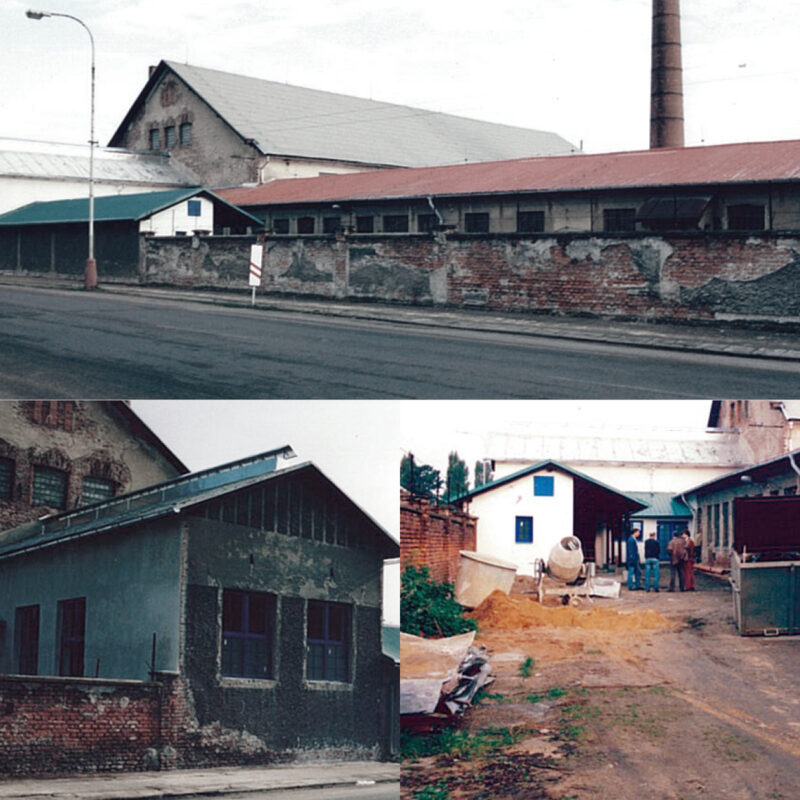

1996

We purchased an old building in Mnichovo Hradiště and started to reconstruct it and turn it into our Production plant. The building was originally a glass factory during the first republic but it was badly damaged during the socialist period. This year we also won the main Golden Crystal prize at the Silicium Bohemica fair.

1995

ECOGLASS became the first Czech serial producer of aspherical lenses, which were imported from abroad until then. Special glass for optoelectronics and dedicated for communication in IR range was developed. Such glass type is used for sensors and manufacturing of rain sensors and automatic wiper systems for the automotive industry. We took part in the Silicium Bohemica trade fair in Prague.

1994

In this year, the production of glass paperweights of various shapes from glass rods by pressing with a final surface was started. The technology of precision optical pressing with final surface was developed in the company including the production equipment. Once the moulds were produced with sufficient precision, the production of technical mouldings, especially aspherical lenses, was started. Aspherical lenses are used in lighting technology – spotlights for the automotive industry, airport lighting, theatre spotlights, etc. For the electronics industry, glass with infrared transmittance has been developed for the moulding of sensors for optical sensors. The company headquarters was moved to the new location, the wife of one of the founders, Mirka Kočárková, joined the company and the picture shows how improvised conditions we started in.

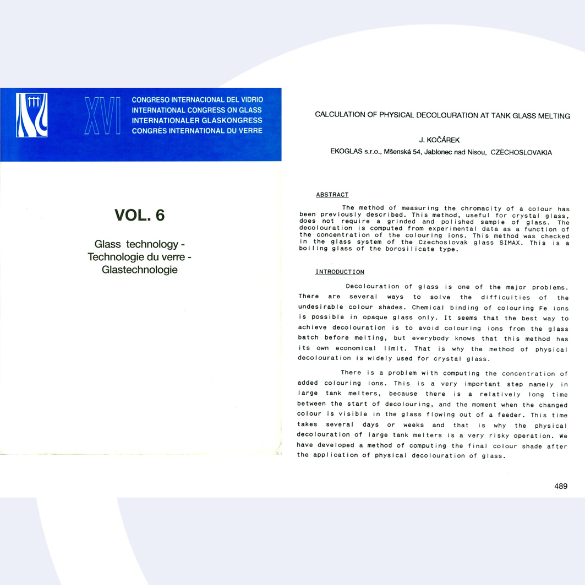

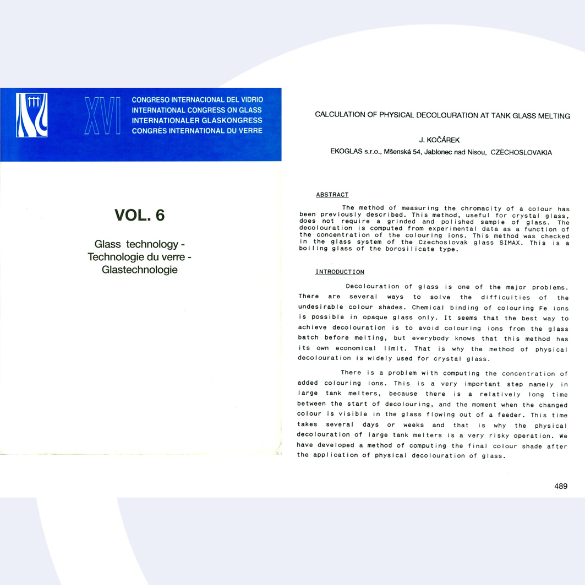

1992

ECOGLASS was given the opportunity to present the results of the development at the International Glass Congress in Madrid.

1991

ECOGLASS was established and entered in the company registry. Main company activities were focused on research and development of glass composition, glass technology and technical advisory to main glass manufacturers in Czechoslovakia and abroad. Company had three partners, who used to work at the Research Institute of Glass and Jewelry in Jablonec nad Nisou and who were at the beginning of the company the only employees.

2021

The management of the company was taken over by the second family generation in September 2021, which is exactly 30 years after the company ‘s establishment. Mr. Jiří Kočárek, the company founder, is still a valuable member or R&D team. His daughter Mrs. Helena Krutská is leading the company as new CEO together with her husband Mr. Jan Krutský, Vice-Chairman of the company Board.

2020

We focused on the promotion of the company into the online world – we set up social networks, participated in online trade fairs and set up Google advertising. Our company won second place in the Vodafone Company of the Year competition in the Liberec region. We started to expand and modernize the production management offices at the production plant in Mnichovo Hradiště.

2019

The working environment was improved thanks to the air extraction system installed in the large press room.

2018

An investment was made in grinding technology for small products, with the aim of reducing dependence on suppliers and improving flexibility in production. ISO 14001 certification was introduced.

2017

Our production is equipped with new 3D scanning technology for complex evaluation of tools and products.

2016

We finished reconstruction and extension of our production plant.

2015

We have enlarged our production facility and extended our tool manufacturing capabilities with a new CNC turning center. We were also nominated as a serial supplier in several automotive projects.

2012

We have extended our development and testing capacities with a new light laboratory including a new goniophotometer. It accelerated our development of optics and its testing.

2010

Inquiries for specific exterior lighting applications are more frequent, customers require lenses including optical design. ECOGLASS invested into software tool for optical design and simulations and started to produce lenses for LED applications.

2008

New prototype pressing machine with high production output of small lenses LED matrix displays used in traffic information signs and variable traffic signs is developed and manufactured. Production of small lenses up to 20mm is maintained in serial deliveries.

2005

We have started production of small lenses for LED matrix displays used in traffic information signs and variable traffic signs. We significantly increased production of glass parts for airport lighting. New 3D measurement device with a resolution of 2.5 microns has been purchased in order to improve inspection of tools and products. New CNC milling center is installed for tool manufacturing. This year we also won the Exporter of the Year competition in the category of small and medium-sized companies and started to reconstruct the new company headquarters.

2002

Production capacity is increased about 3 times by installation of new pressing machines.

2001

We have started deliveries of glass prisms for airfield lighting. And we also modernized and repaired our production hall.

2000

Company manufacturing activities were separated from purely commercial activities and company ownership structure was simplified. EcoGlass became a company owned by a single partner. This year we were nominated for the first time as the supplier for serial production of aspheric lens for automotive headlight – fog light Skoda Octavia.

1999

Quality management system according to ISO 9002 is implemented. Our light laboratory is equipped with precise goniophotometer for evaluation of photometrical parameters of headlamps and functional inspection of aspherical lenses.

1998

We continue on further development of the rain sensor by digitizing its functions and implementing microprocessor control. We have reached precision of molded parts at +/-0.005 mm. We gained the first orders for serial supply of aspheres for motorcycle headlights in Italy.

1997

Brown field manufacturing equipment purchased previous year resulted in better organization of production. Further investments into production technology bringed increase in quality and precision of the products. We started production of parts from borosilicate glass types Duran (Pyrex). This year we held the first republic conference on aspheric optics, its production and use. We exhibited abroad for the first time at the Czech Days event in Chicago.

1996

We purchased an old building in Mnichovo Hradiště and started to reconstruct it and turn it into our Production plant. The building was originally a glass factory during the first republic but it was badly damaged during the socialist period. This year we also won the main Golden Crystal prize at the Silicium Bohemica fair.

1995

We succeed in becoming major serial supplier for customers purchasing aspherical lenses from EcoGlass. Special glass for optoelectronics and dedicated for communication in IR range is developed. Such glass type is used for sensors and manufacturing of rain sensor and automatic wiper system for automotive industry.

1994

In this year, the production of glass paperweights of various shapes from glass rods by pressing with a final surface was started. The technology of precision optical pressing with final surface was developed in the company including the production equipment. Once the moulds were produced with sufficient precision, the production of technical mouldings, especially aspherical lenses, was started. Aspherical lenses are used in lighting technology – spotlights for the automotive industry, airport lighting, theatre spotlights, etc. For the electronics industry, glass with infrared transmittance has been developed for the moulding of sensors for optical sensors. The company headquarters was moved to the new location, the wife of one of the founders, Mirka Kočárková, joined the company and the picture shows how improvised conditions we started in.

1992

ECOGLASS was given the opportunity to present the results of the development at the International Glass Congress in Madrid.

1991

ECOGLASS was established and entered in the company registry. Main company activities were focused on research and development of glass composition, glass technology and technical advisory to main glass manufacturers in Czechoslovakia and abroad. Company had three partners, who used to work at the Research Institute of Glass and Jewelry in Jablonec nad Nisou and who were at the beginning of the company the only employees.